|

| December 15, 2015 | Volume 11 Issue 47 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Designing single-axis drive systems just got easier

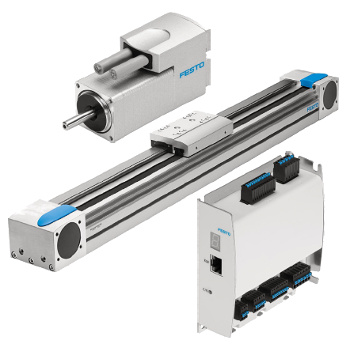

Pneumatic and mechanical components manufacturer Festo has made available "PositioningDrives" productivity software for designing single-axis drive systems. To use it, engineers input application requirements and PositioningDrives details the information necessary to create a Festo component parts list, including electromechanical actuator, motor, drive, software, cables, and other accessories. Festo provides PositioningDrives as a free download.

All of the Festo components in a PositioningDrives single-axis drive bill of materials have been designed to work together, which promotes both operational efficiency and decreased assembly time.

Once the parts list is finalized, it is exported to the Festo Online Shopping Basket for a ready-to-order system. The software also delivers comprehensive documentation about the single-axis system to share with internal teams and end users.

A quick look at the user experience

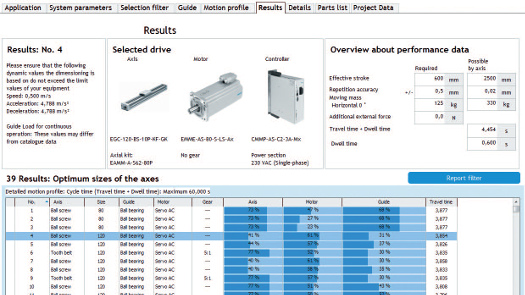

Once application parameters have been entered, the PositioningDrives software identifies various single-axis system combinations from an extensive, harmonized range of components, including electric linear axes, motors, gear units, controllers, and software. Application details entered into PositioningDrives consist of mounting position, load, stroke, and precision. There is also an option to delineate travel time.

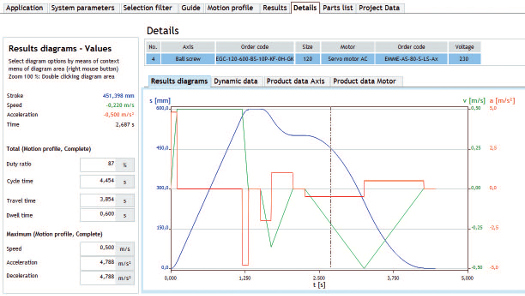

The engineer can use the software to sort options and narrow down the search for the ideal system. In the design process, combinations of axis, motor/gear unit, and controller are displayed graphically, and the degree of utilization is shown as a bar graph. Clicking on a component's illustration opens respective documentation.

The program provides detailed system information such as motion profile, dynamic load, product characteristics, and a bill of materials. Complete project documentation and data backup round out the scope of functions furnished by PositioningDrives.

"Engineers tell us this is a fantastic productivity tool," says Tom Worsnopp, Product Manager of Servopneumatics and PLCs, Festo. "Even if it did not save an incredible amount of time (and it does), they tell us the quality, performance, dependability, and ease of ordering a harmonized motion system is exactly what they want for their machines and their company."

You can learn more about PositioningDrives, view a video tutorial, and download the software at https://www.festo.com/cms/en-us_us/50554.htm.

Source: Festo

Published December 2015

Rate this article

View our terms of use and privacy policy